is part of the Division of Informa PLC

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726. Hdpe Extruder Machine

There was a lot of talk about synergy , when Amut SpA (Novara, Italy), a maker of extruders, thermoformers and plastics recycling equipment, acquired packaging equipment builder Dolci Bielloni in February 2015. That synergy has come to fruition, says the company, now named Amut Dolci Bielloni, with a cast extrusion line for stretch film that achieves a consistent 750 m/min production speed.

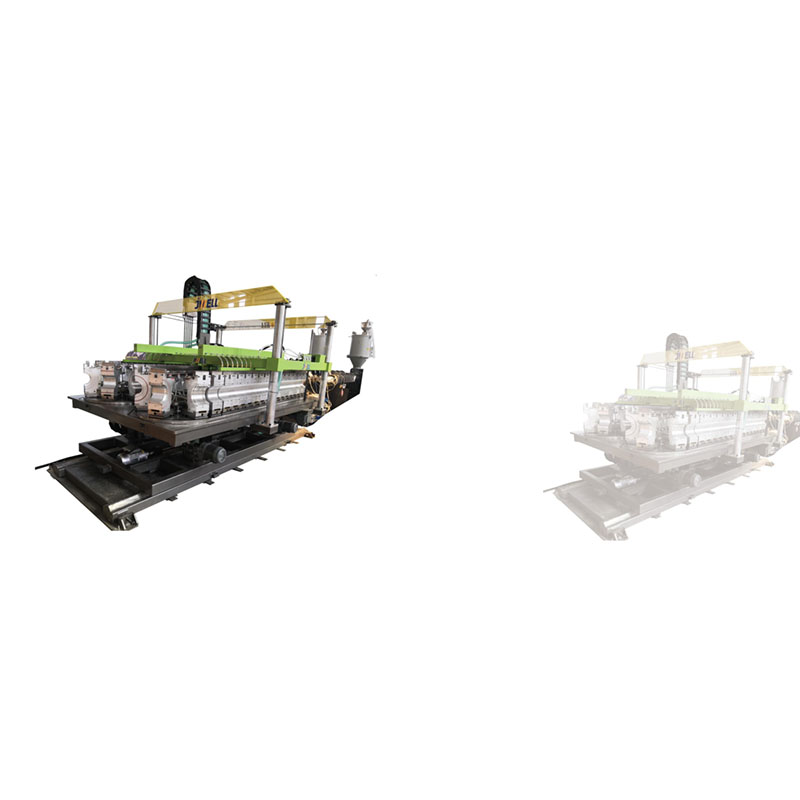

The concept line, which was first introduced at an open house in May, has a seven-layer configuration with six extruders. The 2000- and 3000-mm versions achieve net outputs of 1500 and 2400 kg/h, respectively.

Amut Dolci Bielloni cites the system's following features:

Scrap recovery is done by inserting the fluff on one side of the extruder through a cold channel. A filtration system ensures dust-free fluff collection. The fluff is stored in a dedicated silo during startup and is recovered in-line during processing.

Layout of the extrusion system has been optimized: All of the extruders and accompanying screen changers are mounted in a parallel configuration. This arrangement makes the best use of available space while facilitating maintenance and screen changing operations, according to Amut Dolci Bielloni.

Dual workstations with touch screens allow the operator to work in the chill roll area or near the winder. All relevant parameters are displayed on both workstations.

Before unloading, each roll is weighed to verify that it meets preset parameters. Variations are reported and the line automatically resets as a result.

Extruder Pipe More information about text formats